-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

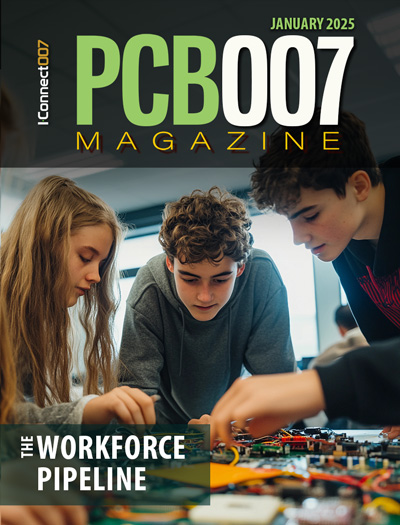

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

Inner Layer Precision & Yields

In this issue, we examine the critical nature of building precisions into your inner layers and assessing their pass/fail status as early as possible. Whether it’s using automation to cut down on handling issues, identifying defects earlier, or replacing an old line...

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Happy’s Essential Skills: Design for Manufacturing and Assembly, Part 1

June 29, 2016 | Happy HoldenEstimated reading time: 9 minutes

Advances in interconnection technologies have occurred in response to the evolution of component packages, electronic technology and increasing complex functions. Therefore, it comes as no surprise that various forms of printed wiring remain the most popular and cost-effective method of interconnections.

Manufacturing, assembly and test technologies have responded by improvements in their technologies. These increased capabilities have made selection of technologies, design rules and features so complex that a new function has developed to allow for the prediction and selection of design parameters and performance versus manufacturing costs. This is the planning for design, fabrication and assembly. This activity has also been called design for manufacturing and assembly (DFM/A) or sometimes predictive engineering. It is essentially the selection of design features and options that promote cost-competitive manufacturing, assembly, and test practices. Later in this column, I will offer a process to define producibility unique to each design or manufacturing process.

The purpose of this column is to provide information, concepts, and processes that lead to a thoughtfully and competitively designed printed circuit, ensuring that all pertinent design and layout variables have been considered.

Originators: Dewhurst & Boothroyd

Modern DFMA stems from the ideas of university professors Goefrey Dewhurst at University of Massachusetts -Amherst and Jeffery Boothroyd at University of Rhode Island [1]. These Manufacturing Engineering professors came up with the concept that you could predict the assembly time, dificulty and cost by cateloging and summing all the kinematic actions it takes during assembly. This concept became so accurate that it was used to predict assembly while a product was still in the design phase. Thus as a predictive metric, it became Design for Manufacturing—DfM. Today this technology is taught in universities and used by most large OEMs around the world. The Dewhurst & Boothroyd software (Table 1 and Figures 1a & b) consists of:

The D&B techniques consist of analyzing an assembly for these features:

- The need for this part

- How many fasteners are required

- The number of different fastener types

- The number of difficult-to-assemble parts or subassemblies

- The number of motions and twist/turns involved in each assembly step

- The role of tooling and fixturing

The resulting analysis shows a:

- Total part count

- Theoretical minimum of parts or preassembled item (Pmin)

- Assembly efficiency (ease of assembly—AE)

- Assembly time

The analysis uses software to measure:

- Prototype evaluations based on either actual or 3D models using Boothroyd and Dewhurst method.

- Pmin is a measure of the complexity of the product. In general, the more functionality there is in a product, the higher the Pmin value.

- Assembly Efficiency (AE) is a ratio of the theoretical minimum number of parts (Pmin) to the estimated assembly time. An approximation is used to compute AE (2.933 seconds per part), so AE values are used for relative comparisons only.

Table 1: The Dewhurst & Boothroyd DFMA software.

Figure 1a: The Dewhurst & Boothroyd DFMA software.

Figure 1b: The Dewhurst & Boothroyd DFMA software.

Page 1 of 4

Suggested Items

I-Connect007 Editor’s Choice: Five Must-Reads for the Week

03/14/2025 | Nolan Johnson, I-Connect007Inside the industry, it feels like we’re getting ready for a big party holiday, and I’m feeling the whole Mardi Gras vibe. This weekend, IPC APEX EXPO kicks off with standards development committees and the Technical Conference before the Expo starts on March 18. We’ll be sneaking out of our network of evil lairs scattered around North America and convening at the I-Connect007 booth in the middle of the Anaheim Convention Center. Be sure to stop by and say hello.

Ainos, ASE Partner to Power AI Scent Digitization in Semiconductor Manufacturing

03/14/2025 | ASE GroupAinos, Inc., a leader in AI-driven scent digitization, has announced a strategic collaboration with Advanced Semiconductor Engineering, Inc. (ASE), the world’s largest provider of semiconductor packaging and testing services.

Michael J. Loparco Joins Sanmina's Board of Directors

03/14/2025 | PRNewswireSanmina Corporation, a leading integrated manufacturing solutions company, today announced the appointment of Michael J. Loparco to the Company's Board of Directors, effective March 10, 2025.

Cybord Unveils AI-Powered Real-Time Interception (RTI) Solution to Prevent Defective Electronic Products

03/14/2025 | PRNewswireCybord, the leading provider of advanced AI-powered electronic component analytics, announced the launch of its Real-Time Interception (RTI) solution, an advanced visual AI-powered software that prevents defective components from being assembled onto Printed Circuit Board Assemblies (PCBAs) in real time.

Vexos Enhances Global Manufacturing Footprint with New Electronics Manufacturing Facility in China

03/13/2025 | EINPresswire.comVexos, a leading global provider of Electronic Manufacturing Services (EMS) and Custom Material Solutions (CMS), is pleased to announce the successful relocation of its China operations to a newly opened, state-of-the-art manufacturing facility in Dongguan, China.