-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

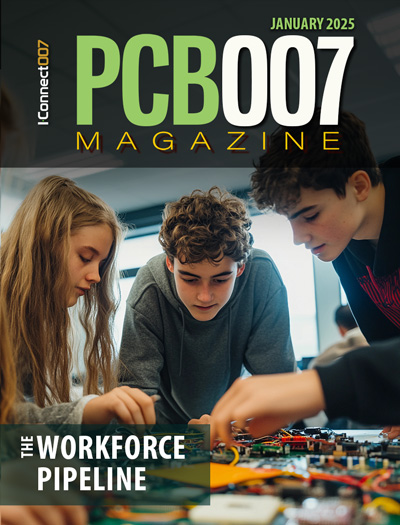

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

Inner Layer Precision & Yields

In this issue, we examine the critical nature of building precisions into your inner layers and assessing their pass/fail status as early as possible. Whether it’s using automation to cut down on handling issues, identifying defects earlier, or replacing an old line...

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

UHDI Fundamentals: UHDI Bleeding-edge Manufacturing Applications, Part 1

November 14, 2024 | Anaya Vardya, American Standard CircuitsEstimated reading time: 1 minute

Last month, I talked about ultra high definition interconnect (UHDI) in relation to entertainment applications. This month, I will explain bleeding-edge UHDI applications in manufacturing, which are revolutionizing the industry by enabling ultra-precise visual data transmission, high-speed communication between devices, and real-time monitoring. These UHDI technologies help manufacturers achieve higher efficiency, better quality control, and greater automation. Following are some leading-edge manufacturing applications of UHDI in manufacturing.

Precision Machine Vision Systems

- 8K and 16K cameras for quality control: UHDI enables ultra-high-definition cameras (up to 16K resolution) to be used in machine vision systems, providing incredibly detailed inspections of products. These cameras can detect microscopic defects in components and materials, ensuring flawless quality control. UHDIs facilitate the real-time transfer of massive image data to processors for immediate analysis, reducing error rates and improving product consistency.

- Real-time defect detection: With UHDI-enabled cameras, defects in high-speed production lines can be detected instantly. The high-definition imagery allows for more precise automated visual inspections, even in complex manufacturing processes like semiconductor fabrication or pharmaceuticals.

Robotics and Automation

- High-resolution vision for robotic systems: UHDI plays a critical role in enhancing robotic vision by delivering high-definition visual data to robots. This allows robots to perform highly complex tasks that require extreme precision, such as electronic component placement, welding, or assembling small parts in automotive manufacturing. The higher resolution from UHDI gives robots the capability to work with greater accuracy and at higher speeds.

- Collaborative robots (cobots): UHDI technologies enhance cobots by providing them with more detailed visual feedback. These robots work alongside humans in tasks like product assembly or material handling. UHDI enables real-time visual monitoring and precise control, ensuring cobots operate safely and efficiently.

Continue reading this article in the November 2024 issue of Design007 Magazine.

Suggested Items

Are Domestic Assemblers Ready for the Next Level of Electronics Miniaturization?

02/19/2025 | Chrys Shea, SHEA Engineering ServicesUHDI technology is more than another evolutionary level of miniaturization. It’s a fundamental change in how we create circuit boards, on a scale potentially as impactful as the transition from through-hole to surface mount was 40 years ago.

UHDI Fundamentals: UHDI Bleeding-edge Entertainment Applications, Part 2

02/06/2025 | Anaya Vardya, American Standard CircuitsUltra high density interconnect (UHDI) technology is revolutionizing bleeding-edge entertainment applications by enabling compact, high-performance devices that push the boundaries of immersion, interactivity, and realism. Part 2 focuses on how UHDI is advancing the entertainment industry, particularly gaming.

Happy’s Tech Talk #37: New Ultra HDI Materials

02/03/2025 | Happy Holden -- Column: Happy’s Tech TalkSome new materials have been introduced in the past year for ultra high density interconnect (UHDI), a convenient title for developing high density technologies. They have received labels like semiconductor-like PCBs (SLPs), redistribution layers (RDL), flip-chip ball grid array (FCBGA), and interposers. The early 2000s saw the creation of these organic substrates for flip-chip IC packaging. The initial construction was composed of a BT core with build-up layers of the Ajinomoto Build-up Film (ABF)

SMTA UHDI Symposium 2025, Part 2: State of the Art

01/29/2025 | Marcy LaRont, I-Connect007A group of about 50 attended the second annual SMTA Ultra High Density Interconnect Symposium on Jan. 23, 2025. After a morning of technical presentations on challenges and solutions regarding UHDI technology, we gathered for a delicious Mexican buffet lunch and some networking before reconvening for an afternoon of more technical topics.

SMTA UHDI Symposium 2025, Part 1: Challenges and Solutions

01/28/2025 | Marcy LaRont, I-Connect007SMTA hosted its second annual Ultra High Density Interconnect Symposium, a conference on cutting-edge PCB technology, on Jan. 23, 2025, at the Peoria Sports Complex in Arizona. A highly pro-business state with a special affection for the tech sector, Arizona is home to the biggest Intel semiconductor fab in the United States and the new TSMC chip fab. With an intimate group of approximately 50 attendees, the SMTA event offered a great forum for learning, interactive discussion, and networking.