-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

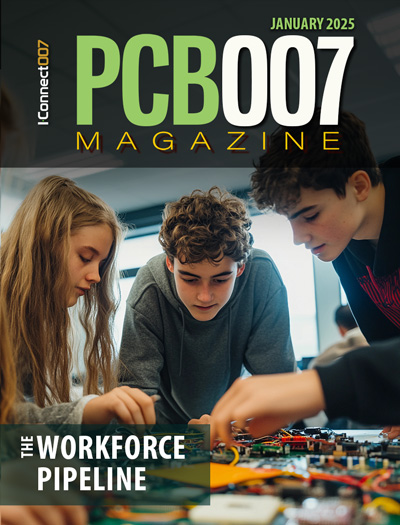

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

Inner Layer Precision & Yields

In this issue, we examine the critical nature of building precisions into your inner layers and assessing their pass/fail status as early as possible. Whether it’s using automation to cut down on handling issues, identifying defects earlier, or replacing an old line...

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Land O'Frost Reduces Daily Labor Expenses by 20% While Upskilling Its Workforce with Formic Robots

February 6, 2025 | BUSINESS WIREEstimated reading time: 2 minutes

Formic, a Robots-as-a-Service (RaaS) automation provider for U.S. manufacturers, deployed five gantry-style palletizing robots at Land O’Frost’s Lansing, Illinois, manufacturing facility, saving them 20% on labor-related OpEx daily and transitioning employees from manually stacking boxes onto pallets to being robot operators. Formic’s Full Service Palletizer Rental program optimized end-of-line production, increasing safety and production while bolstering employee skills from day one.

Land O’Frost’s key drivers for adding production line automation with Formic were improving employee safety, speeding changeovers in production, and eliminating repetitive SKU packing pattern training. The company runs multiple SKUs, resulting in a new pallet pattern with every product changeover. On the production floor, this required continual retraining — taking away valuable time from floor operators that could have been spent on productivity-increasing tasks for the business.

“When I saw the opportunity for automation to eliminate repetitive production line tasks while simultaneously improving our employees’ lives, it was an easy decision,” said Frank Mejia, Continuous Improvement Supervisor at Land O’Frost. “Formic made the entire deployment process simple. They took care of everything, from training our team on the machines to handling all future maintenance.”

Formic deployed all five systems over two weekends while production ran unhindered, programmed pallet patterns for all SKUs, and trained all floor operators on the robotic systems. Since deployment, Land O’Frost has realized a 20% savings on labor-related OpEx daily, while reducing the changeover process from lengthy discussions between employees to a few clicks on a touchscreen.

“Land O’Frost has always focused on finding new ways to innovate their production processes, which is how they’ve continually grown since their founding in the 1940s,” said Saman Farid, Formic’s Founder and CEO. “By adding our palletizing solutions to their production line, they’ve eliminated unnecessary downtime, upskilled employees to robot operators, and reduced overall OpEx spend. Automation was the final missing piece in driving their production efficiency even further.”

Formic’s Full Service Palletizer Rental program includes access to four fully supported turnkey palletizing solutions for the same fixed monthly or annual rate. The program also includes 24/7 technical support, 100% preventative and corrective maintenance coverage, contracted performance rates, equipment swapping at no extra cost, and lead times of 10 weeks or less.

On April 30th, Land O’Frost will host a Formic Automation Community event at their Illinois facility to showcase how our robotic solutions are supporting the production of 128,000 pounds of meat daily.

Suggested Items

EV Solid-State Battery Validation Accelerates in the U.S. and Europe, Mass Production Expected to Gradually Begin by 2026

03/13/2025 | TrendForceTrendForce’s latest research reveals that solid-state batteries are emerging as the next-generation battery technology with high commercial potential. Manufacturers across the U.S., Europe, and other global markets are accelerating large-scale production development and performance validation for automotive applications.

Eltek Reports Full Year and Q4 2024 Financial Results

03/13/2025 | EltekEltek Ltd., a global manufacturer and supplier of technologically advanced solutions in the field of printed circuit boards (PCBs), today announced its financial results for the full year and fourth quarter ended December 31, 2024.

YINCAE: UF 158UL Redefines Underfill for Large Chips

03/12/2025 | YINCAEYINCAE, a leading innovator in advanced materials solutions, today announced the launch of its groundbreaking underfill material, UF 158UL. This cutting-edge product is designed to meet the increasing demands of large format chips, offering unparalleled performance in room temperature flow, fast cure, and high reliability.

AIM Solder Partners with Performance Technologies Group for Sales Representation in Northeast US

03/12/2025 | AIM SolderAIM Solder, a global leader in solder assembly materials for the electronics industry, is excited to announce its new partnership with Performance Technologies Group, Inc. (PTG), an established electronic manufacturers’ representative.

Apple’s Year-End Production Peak and China’s Subsidy Policies Drive 9.2% QoQ Growth in 4Q24 Smartphone Production

03/11/2025 | TrendForceTrendForce reports that global smartphone production in the last quarter of 2024 reached 334.5 million units, reflecting a 9.2% QoQ increase, driven by Apple’s peak production season and consumer subsidies from local Chinese governments.