-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

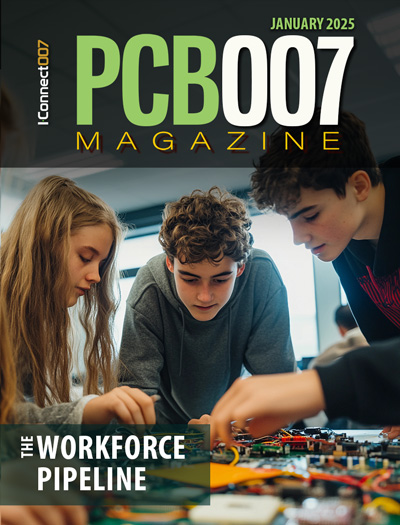

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

Inner Layer Precision & Yields

In this issue, we examine the critical nature of building precisions into your inner layers and assessing their pass/fail status as early as possible. Whether it’s using automation to cut down on handling issues, identifying defects earlier, or replacing an old line...

Engineering Economics

The real cost to manufacture a PCB encompasses everything that goes into making the product: the materials and other value-added supplies, machine and personnel costs, and most importantly, your quality. A hard look at real costs seems wholly appropriate.

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

MKS' Atotech: More Horizontal Panel Plating in the U.S.

October 11, 2023 | Christopher R. Daczkowski, MKS' AtotechEstimated reading time: 1 minute

Recently, Schweitzer Engineering Laboratories (SEL) opened its new $100 million captive printed circuit board manufacturing facility in Moscow, Idaho. The new facility features state-of-the-art PCB equipment from MKS’ Atotech, one of the leading providers of advanced PCB and IC substrate horizontal manufacturing equipment for the electronics industry. This type of equipment is normally delivered to Asian markets and is not usually seen in North America.

Equipment selection is a crucial decision for any company and directly impacts the quality and efficiency of production processes. For our customers, several key factors usually drive the decision to install MKS’ Atotech equipment lines. These include our long history as a reputable global solutions provider and proven record of successful installations worldwide. Today, we have delivered and installed more than 2,150 horizontal PCB lines for surface treatment, desmear and metallization, copper electroplating, and final finishing of printed circuit boards and IC substrates, of which more than 1,000 are horizontal copper platers. They are well known for their outstanding repeatability of copper deposition uniformity and pure copper plating results.

With the shift toward increased investment in local manufacturing in the U.S., our system solutions are appreciated as high-quality products to support manufacturing demand now and in the future. With our long history in the Americas, we are happy to see this development and are excited to provide the best possible technical support to our customer base, which is growing, especially with the trend of opening new, innovative PCB plants.

Follow this link to continue reading this article which appears in its entirety in the September 2023 issue of PCB007 Magazine.

Suggested Items

Designers Notebook: Addressing Future Challenges for Designers

02/06/2025 | Vern Solberg -- Column: Designer's NotebookThe printed circuit board is and will probably continue to be the base platform for most electronics. With the proliferation of new generations of high I/O, fine-pitch surface mount semiconductor package variations, circuit interconnect is an insignificant factor. Circuit board designers continually face challenges such as component quantity and complexity, limited surface area, and meeting the circuit board’s cost target. The printed circuit design engineer’s prominent position demands the development of efficiently manufacturable products that perform without compromise.

DesignCon 2025, Day 2: It’s All About AI

01/30/2025 | Marcy LaRont, I-Connect007It’s hard to get away from the topic of artificial intelligence, but why would you? It’s everywhere and in everything, and my time attending presentations about AI at DesignCon 2025 was well worth it. The conference’s agenda featured engaging presentations and discussions focused on the technological advancements in AI, big data centers, and memory innovations, emphasizing the critical relationship between processors and circuit boards.

Beyond Design: Electro-optical Circuit Boards

01/22/2025 | Barry Olney -- Column: Beyond DesignPredicting the role of PCB designers in 10 years is a challenge. If only I had a crystal ball. However, we know that as technology progresses, the limitations of copper PCBs are increasingly apparent, particularly regarding speed, bandwidth, and signal integrity. Innovations such as optical interconnects and photonic integrated circuits are setting the stage for the next generation of PCBs, delivering higher performance and efficiency. The future of PCB design will probably incorporate these new technologies to address the challenges of traditional copper-based designs.

Designers Notebook: Impact of Advanced Semiconductor Packaging on PCB Stackup

01/07/2025 | Vern Solberg -- Column: Designer's NotebookTo accommodate new generations of high I/O semiconductor packaging, printed circuit board fabrication technology has had to undergo significant changes in both the process methods and the criteria for base material selection and construction sequence (stackup). Many of the new high-function multi-core semiconductor package families require more terminals than their predecessors, requiring a significantly narrower terminal pitch. Interconnecting these very fine-pitch, high I/O semiconductors to the PCB is made possible by an intermediate element referred to as an interposer.

BOOK EXCERPT: The Printed Circuit Designer’s Guide to... High Performance Materials, Chapter 4

01/02/2025 | I-Connect007In Chapter 4, Michael Gay discusses the two main types of copper foil used for PCB boards today: electrodeposited (ED) foil and rolled annealed (RA) foil. He also explains the pros and cons of each, and provides an update of the latest innovations in copper foil technology.