-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

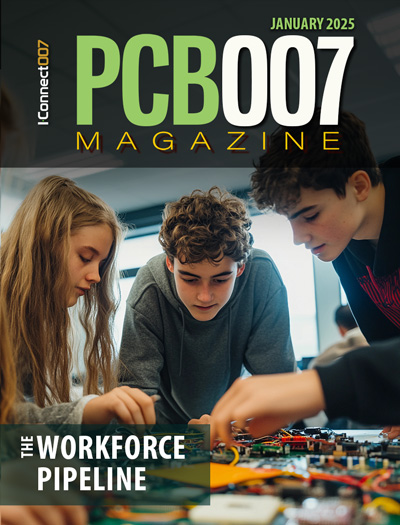

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

Inner Layer Precision & Yields

In this issue, we examine the critical nature of building precisions into your inner layers and assessing their pass/fail status as early as possible. Whether it’s using automation to cut down on handling issues, identifying defects earlier, or replacing an old line...

Engineering Economics

The real cost to manufacture a PCB encompasses everything that goes into making the product: the materials and other value-added supplies, machine and personnel costs, and most importantly, your quality. A hard look at real costs seems wholly appropriate.

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Lockheed Martin, NVIDIA Demonstrate AI-Driven Digital Twin With Potential To Advance Predictive Forecasting

January 31, 2024 | Lockheed MartinEstimated reading time: 2 minutes

In a year where the National Oceanic and Atmospheric Administration (NOAA) has reported record ocean temperatures, an innovative project from Lockheed Martin, built in collaboration with NVIDIA, is showing how artificial intelligence can be used to fuse data and detect anomalies in current environmental conditions.

Since 2022, Lockheed Martin has collaborated with NVIDIA to build a prototype of an AI-driven Earth and Space Observing Digital Twin that can:

- Process live streams of incoming weather data, apply AI and machine learning to analyze the data,

- Display current global environmental conditions from satellite and ground-based observations and output from weather forecasting models.

Recently, the project achieved a significant milestone, demonstrating one of NOAA’s critical data pipelines – sea surface temperatures – to highlight multi-sensor fusion from satellite and model data along with short term temperature anomalies.

The Earth and Space Observing Digital Twin aims to provide NOAA with an efficient and centralized approach to fuse and visualize data from various space and earth sensors. The demo showed NOAA and other government customers the potential of using AI to display high-resolution, accurate, and timely depictions of satellites and sensor data.

“A platform such as our digital twin could serve as a one-stop-shop for global weather monitoring and could enable more accurate initial conditions for predictive forecasting,” said Lynn Montgomery, AI research engineer at Lockheed Martin. “Every day, NOAA receives terabytes of weather data from numerous space and Earth-based sensors, and this project helps fuse this information accurately to support timely depiction of global conditions.”

The project uses Lockheed Martin’s OpenRosetta3D software and the NVIDIA Omniverse development platform to build applications that aggregate data in real time. The Digital Twin uses these technologies to advance 4D visualizations and display this information in a digestible format.

“From monitoring current environmental conditions to predicting them, digital twins can help climate and weather enterprises tackle their toughest AI and forecasting challenges,” said Dion Harris, director of accelerated computing product solutions at NVIDIA. “This latest milestone in our collaborative efforts demonstrates how NVIDIA Omniverse can quickly synthesize terabytes of NOAA data from a large number of sources to speed up global weather monitoring and prediction.”

Lockheed Martin’s next plans are to incorporate additional data streams — such as space weather and sea ice concentrations — into the Earth and Space Observing Digital Twin next year.

This project was funded by NOAA SAE Joint Venture Partnerships for the exploration of possibilities for a future state and not a mission itself.

Suggested Items

DesignCon 2025, Day 2: It’s All About AI

01/30/2025 | Marcy LaRont, I-Connect007It’s hard to get away from the topic of artificial intelligence, but why would you? It’s everywhere and in everything, and my time attending presentations about AI at DesignCon 2025 was well worth it. The conference’s agenda featured engaging presentations and discussions focused on the technological advancements in AI, big data centers, and memory innovations, emphasizing the critical relationship between processors and circuit boards.

ASMPT Simplifies High-Mix SMT Production with Automated Program Changeovers

01/30/2025 | ASMPTASMPT, the global market and technology leader in hardware and software solutions for semiconductor and electronics manufacturing, has implemented another step in automating product changeovers on the SMT line.

Rising AI Infrastructure Demand Highlights Industry Shift Toward Cost-Effective Solutions as DeepSeek Gains Traction

01/30/2025 | TrendForceTrendForce’s latest investigations have revealed that the recent release of DeepSeek-V3 and DeepSeek-R1 underscores an industry-wide shift toward more cost-effective AI infrastructure.

Bajaj Electronics Supercharges Digital Transformation with Google Workspace and Brio Technologies

01/28/2025 | PRNewswireBajaj Electronics, a leading consumer electronics retailer, has modernized its operations by migrating to Google Workspace with the assistance of Brio Technologies, a specialized Google Cloud partner.

IDC Predicts: AI Spending to Exceed $30 Billion by 2027 for Personalized Customer Experiences

01/28/2025 | IDCThe recent IDC report, IDC FutureScape: Worldwide Chief Marketing Officer 2025 Predictions – APeJ Implications, predicts that In 2027, companies will spend more than US$30 billion on AI-related infrastructure, platforms, software, and services to support their ability to compete on highly personalized customer experiences.