-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

The Essential Guide to Surface Finishes

We go back to basics this month with a recount of a little history, and look forward to addressing the many challenges that high density, high frequency, adhesion, SI, and corrosion concerns for harsh environments bring to the fore. We compare and contrast surface finishes by type and application, take a hard look at the many iterations of gold plating, and address palladium as a surface finish.

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

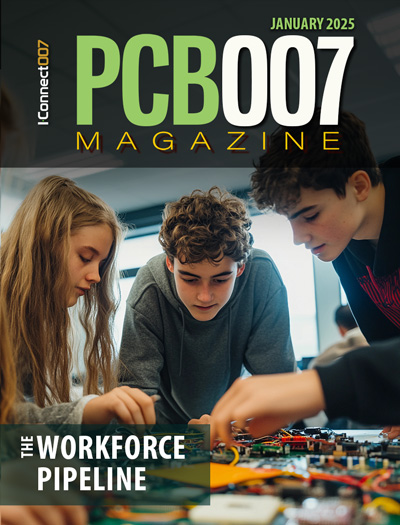

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Tata Advanced Systems and Airbus Inaugurate C295 Final Assembly Line in Vadodara, India

October 30, 2024 | AirbusEstimated reading time: 3 minutes

As a major milestone for India’s Aerospace & Defence industry, Tata Advanced Systems Limited (TASL) and Airbus inaugurated the Final Assembly Line (FAL) complex for the Airbus C295 aircraft in Vadodara, Gujarat in India. TASL and Airbus are partnering for the pioneering ‘Make in India’ project to deliver 56 C295 aircraft to the Indian Air Force (IAF). The state-of-the-art facility was inaugurated by the Prime Minister of India, Shri. Narendra Modi and the President of the Government of Spain, Pedro Sánchez Pérez-Castejón in the presence of N. Chandrasekaran, Chairman of Tata Sons and Michael Schoellhorn, CEO of Airbus Defence and Space.

Providing a major boost to the Government of India’s 'AatmaNirbhar Bharat’ (self-reliant India) programme, this is the first instance of the private sector setting up an aircraft FAL in India. The inauguration comes three years after the IAF formalised the acquisition of 56 Airbus C295 aircraft to replace their legacy AVRO fleet. As per the contract, 40 units will be manufactured and assembled in partnership with TASL at this FAL, while 16 will be delivered to the IAF in ‘fly-away’ condition from Airbus’ final assembly line in Seville, Spain. To date, a total of six aircraft have already been delivered.

N. Chandrasekaran, Chairman of Tata Sons, said, "The Tata Group is very proud in setting up this advanced facility which will manufacture the nation’s first private defence aircraft from the ground up. It will significantly enhance both defence and advance manufacturing capabilities. I am thankful to Hon'ble Prime Minister Shri Narendra Modi, Hon’ble Pedro Sánchez Pérez-Castejón and the distinguished guests for joining us at this momentous occasion in India's indigenous manufacturing journey."

“The inauguration of this final assembly line (FAL) is a significant milestone in India’s journey towards self-reliance in defence manufacturing. The C295 India programme demonstrates Airbus’ commitment to supporting India’s vision of ‘AatmaNirbhar Bharat’ in defence manufacturing. Aligned to this vision, this FAL will propel the advancement of the aerospace industrial ecosystem in the country, unlocking the potential for cutting-edge design, component manufacturing, aircraft assembly and services capabilities across the Indian value chain,” said Michael Schoellhorn, CEO of Airbus Defence and Space.

The FAL will integrate manufacturing of detail parts and related tooling, sub-assemblies, major component assemblies, tools, jigs and testers. The production of components of the C295 aircraft have already started in the Main Component Assembly (MCA) facility in Hyderabad. The parts for the first C295 aircraft to be made in India have been shipped to the Vadodara FAL, where the aircraft will be assembled and then delivered to the IAF.

Tata Advanced Systems and Airbus inaugurate C295 Final Assembly Line in Vadodara - India

The first ‘Make in India’ C295 will roll out of the Vadodara FAL in September 2026, which will be a milestone for the Indian aerospace industry; and shall ramp-up to deliver 40 aircraft to the IAF by August 2031, as required by the IAF contract.

India has become the largest customer for the C295, with the acquisition of 56 aircraft. The C295 ‘Make in India’ programme will produce more than 85% structural and final assembly of 40 aircraft along with the manufacturing of 13,000 detail parts in India, for which 21 special processes have been certified and 37 India-based suppliers, both from the private and public sectors, have been onboarded.

For Airbus, India is a strategic resource hub where the company is expanding its industrial footprint with aircraft assembly, component manufacturing, engineering design and development, MRO support, pilot and maintenance training as well as academic collaboration to foster human capital. Airbus invests more than $1 billion every year in a robust and comprehensive supply chain in India for components and services, generating more than 15,000 jobs. Additionally, Airbus India’s own engineering and digital centres in Bengaluru contribute to all the commercial and helicopter programmes of Airbus globally.

Suggested Items

Universal Avionics Connected FMS Certified on Part 25 Aircraft Models

04/01/2025 | Universal AvionicsUniversal Avionics (UA), an Elbit Systems company, today announces that FAA certification has been achieved for the installation of its Wi-Fi-enabled Flight Management System (FMS) on Part 25 aircraft models. The Approved Model List Supplemental Type Certificate (AML STC) serves as the foundation for the deployment of Universal’s Connected Avionics onto aircraft.

Airbus Advances Key Technologies for Next-Generation Single-Aisle Aircraft

03/25/2025 | AirbusDuring the 2025 Airbus Summit, Airbus provided an update on its roadmap to pioneer the future of commercial aviation in the decades to come.

Sikorsky Successfully Flies Rotor Blown Wing UAS in Helicopter and Airplane Modes

03/10/2025 | Lockheed MartinSikorsky, a Lockheed Martin company has successfully validated the advanced control laws to successfully fly a ‘rotor blown wing’ uncrewed aerial system (UAS) in both helicopter and airplane modes.

Air Taxis Poised for Mass Adoption as Honeywell Survey Highlights Consumer Interest

03/06/2025 | HoneywellHoneywell released new survey results showing nearly all U.S. airline fliers (98%) would consider taking an electric vertical take-off and landing vehicle, or eVTOL, as part of their travel journey

RTX's Collins Aerospace EPACS Power and Thermal Management System Ready for Aircraft Integration

03/04/2025 | RTXCollins Aerospace, an RTX business, has successfully tested a fully functional demonstrator of its next-generation power and thermal management system (PTMS).