-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

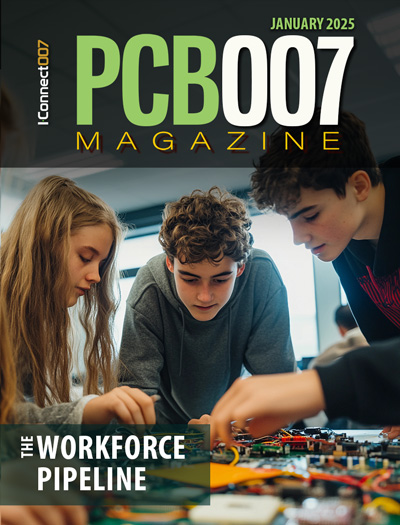

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

Inner Layer Precision & Yields

In this issue, we examine the critical nature of building precisions into your inner layers and assessing their pass/fail status as early as possible. Whether it’s using automation to cut down on handling issues, identifying defects earlier, or replacing an old line...

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Challenges in Modern PCB Design and Analysis

September 5, 2023 | Steve Watt, ZukenEstimated reading time: 1 minute

Navigating the complex landscape of modern PCB design presents numerous challenges for designers and the processes they use. Concerns about time to market, performance, system-level design, requirements, costs, and staffing are driving forces that shape the evolution of the modern PCB industry.

Zuken recognizes the need to address innovation in all areas of the design process while remaining responsive to customer-driven requirements. While we can make predictions about various challenges, concerns, and requirements, our customers play a vital role in shaping the company’s development direction. They have the benefit of being “in the trenches,” so to speak, on a daily basis, so they are the subject matter experts and can help identify gaps in our tools based on where their processes are heading.

System-level Analysis

The new era of electronic systems is characterized by increasing complexity. The demand for higher data rates, lower power consumption, and smaller form factors drive this surge in complexity. As a result, the challenges of managing signal integrity (SI), power integrity (PI), and electromagnetic interference (EMI) are also increasing.

To tackle these challenges, performing system-level SI, PI, and EMI analysis is imperative. This means the entire system must be considered, including different boards, cables, and other components. This comprehensive approach allows engineers to identify and address SI and PI problems before they lead to potential system failures. Engineers can proactively mitigate SI, PI, and EMI problems by delving into system-level analysis, which ensures robust system performance.

To read this entire article, which appeared in the August 2023 issue of Design007 Magazine, click here.

Suggested Items

Ventec International Group Announce Launch of VT-47LT IPC410/126 Prepreg for HDI

03/12/2025 | Ventec International GroupVentec International Group announce launch of VT-47LT IPC4101 / 126 Prepreg. Are Microvia Failures Plaguing Your HDI Any Layer Designs? High-density interconnect (HDI) designs are pushing the envelope - higher layer count HDI relies on complex microvia designs: skip vias, staggered microvias, and stacked microvias in sequential laminations.

TI Introduces the World's Smallest MCU, Enabling Innovation in the Tiniest of Applications

03/12/2025 | PRNewswireTexas Instruments (TI) introduced the world's smallest MCU, expanding its comprehensive Arm® Cortex®-M0+ MSPM0 MCU portfolio. Measuring only 1.38mm2, about the size of a black pepper flake, the wafer chip-scale package (WCSP) for the MSPM0C1104 MCU enables designers to optimize board space in applications such as medical wearables and personal electronics, without compromising performance.

Speaking the Same Language as Your Fabricator

03/12/2025 | Andy Shaughnessy, Design007 MagazineWe do indeed have a failure to communicate; designers and fabricators often seem to be talking past each other, which can lead to jobs being put on hold. We asked Jen Kolar, VP of engineering for Monsoon Solutions, and columnist Kelly Dack to share their thoughts on ways that we can break down the communication barrier between design and fabrication. As they point out, a design kickoff checklist and a solid review process can be invaluable tools in a designer’s toolbox.

IPC Releases Latest List of Standards and Revisions

03/12/2025 | IPCEach quarter, IPC releases a list of standards that are new or have been updated. To view a complete list of newly published standards and standards revisions, translations, proposed standards for ballot, final drafts for industry review, working drafts, and project approvals, visit ipc.org/status. These are the latest releases for Q1 2025.

The Shaughnessy Report: Breaking Down the Language Barrier

03/11/2025 | Andy Shaughnessy -- Column: The Shaughnessy ReportAccording to Ethnologue’s 2024 update, there are currently 7,164 living languages being spoken today. It makes you wonder: Do they count PCB design as a language? PCB fabrication? Assembly?