-

- News

- Books

Featured Books

- pcb007 Magazine

Latest Issues

Current Issue

The Essential Guide to Surface Finishes

We go back to basics this month with a recount of a little history, and look forward to addressing the many challenges that high density, high frequency, adhesion, SI, and corrosion concerns for harsh environments bring to the fore. We compare and contrast surface finishes by type and application, take a hard look at the many iterations of gold plating, and address palladium as a surface finish.

It's Show Time!

In this month’s issue of PCB007 Magazine we reimagine the possibilities featuring stories all about IPC APEX EXPO 2025—covering what to look forward to, and what you don’t want to miss.

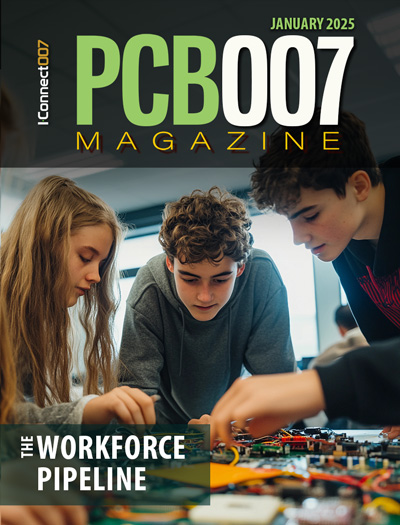

Fueling the Workforce Pipeline

We take a hard look at fueling the workforce pipeline, specifically at the early introduction of manufacturing concepts and business to young people in this issue of PCB007 Magazine.

- Articles

- Columns

Search Console

- Links

- Media kit

||| MENU - pcb007 Magazine

Kinwong Electronics Earns ISO14067 Carbon Footprint Certification

January 29, 2024 | Kinwong ElectronicsEstimated reading time: 2 minutes

The carbon footprint certification project of four rigid printed circuit boards of Kinwong Electronics has been reviewed and approved by a third-party certification body and obtained the ISO14067 carbon footprint certification.

Carbon footprints are a way for organizations and individuals to evaluate the contribution of greenhouse gas emissions to climate change. A product's carbon footprint describes the level of greenhouse gas emissions from an individual product. ISO14067 is a standard developed by the International Organization for Standardization (ISO) to solve the specific calculation method of "carbon footprint".

The system boundary of the carbon footprint of the PCB products is the whole life cycle product carbon footprint accounting, and the carbon footprint system boundary includes five stages: product raw material production and acquisition stage, product production, product transportation and distribution, consumer use, and waste disposal stage.

The on-site accounting data is collected by the environmental management department of the Jiangxi production base, and the production\process\ equipment\ planning \ procurement departments, and other relevant departments jointly assist in providing it. The third-party certification body determines all the raw materials used in the product through the data provided by the company, and uses the world's leading LCA analysis software Sima Pro database to find the carbon emission factors of the corresponding raw materials; Through the production process of the product and the use of energy in each process in the production process, the carbon emission factor in the energy quantity is calculated; Then, through the upstream and downstream transportation means and transportation distance of the product, the transportation emission factor is calculated; Finally, the waste disposal emission factor is calculated through the solid waste generated in the production process of the product.

Through this carbon footprint certification project, Kinwong has met the management requirements of key customers for our company's carbon emissions, and at the same time, it has a basic understanding of the carbon emissions of the company's rigid printed circuit boards in the relevant life cycle stages, including raw material procurement, production, use, and scrap disposal. It can better help enterprises to formulate "carbon emission reduction" goals, so that products can play an important reference role in energy conservation and emission reduction in the production process, optimization of raw materials, etc. It can help enterprises cross the green threshold of the market, establish a green brand, better meet customers, and improve market competitiveness.

Kinwong Electronics has embraced the SDGs

Sustainable Development Goals which were introduced by the United Nations, and has made them the cornerstone of the Group's sustainable management. The group is taking action to protect the environment and reduce waste, Each PCB factory will replace approximately 2.08 million cubic meters of tap water with reused water, increasing the proportion of reused water to a maximum of 45%. By 2025, the proportion of reused water will increase to 60% across the Group. Kinwong will collaborate with hydropower, wind power, and other green power supply enterprises to ensure a stable source of green power for its factories. By 2050, the Group aims to use 200 million KWH of hydropower, wind power, and other green power, resulting in a reduction of 189,780 tons of carbon dioxide. Purchase or lease undeveloped land to plant trees for carbon sequestration. By 2025, the Group aims to plant 10,000 mu of trees, resulting in the sequestration of 244,550 tonnes of carbon dioxide per year. Kinwong implemented the ISO 14064 greenhouse gas emissions system and improved greenhouse gas emissions accounting based on the system; (all baselines completed by 2023).

Suggested Items

UNIST Partners with Fincantieri to Advance Eco-Friendly Energy Technologies

03/24/2025 | UNISTUNIST has entered into a strategic partnership with Fincantieri, Europe’s largest shipbuilder based in Trieste, Italy. Together, the two organizations aim to foster open innovation in the development of eco-friendly energy technologies through robust industry-university collaboration and support for technology startups.

Hitachi Energy Gains National Green Factory Recognition for Two More Facilities in China

03/24/2025 | Hitachi EnergyChina’s Ministry of Industry and Information Technology (MIIT) recently announced its 2024 Green Manufacturing List, with two of Hitachi Energy's local manufacturing bases in Beijing and Datong in north China’s Shanxi Province, receiving the titles of National Green Factory. This brings the total number of Hitachi Energy's local enterprises on the list to four.

Semiconductor Climate Consortium Announces Key 2025 Initiatives to Accelerate

03/04/2025 | SEMIThe Semiconductor Climate Consortium (SCC) unveiled its four key initiatives for 2025, marking a significant step forward in advancing the industry’s commitment to decarbonization and transparency.

SEMI Energy Collaborative Releases Recommendations for Building Low-Carbon Energy Supply in Singapore

02/27/2025 | SEMIThe SEMI Energy Collaborative publicly released its analysis and report: Challenges and Potential Solutions for Acceleration of Low-Carbon Energy Deployment in Singapore.

Airbus-built Biomass Forest Measuring Satellite Shipped to Kourou

02/21/2025 | AirbusBiomass, the European Space Agency’s (ESA) Airbus-built satellite, has left Toulouse for its journey by ship to Kourou, French Guiana, ready for launch.